centrifugal industry|centrifugal pump designs : Big box store The global centrifugal pump market size was valued at USD 50.42 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 3.5% from 2023 to 2030. A laboratory sterilizer – also commonly referred to as an autoclave – is an essential piece of equipment that utilizes pressurized steam to kill microorganisms, such as bacteria, viruses, and spores that may be present .

{plog:ftitle_list}

Discover premium sterilising and autoclave equipment from leading brands like Sterex and Taiji. Ensure top hygiene standards in your beauty salon or spa effortlessly.We have repaired just about every autoclave on the market, and continue to repair them everyday. Our guidance is based on that experience. Our Troubleshooting Guides & Technical .

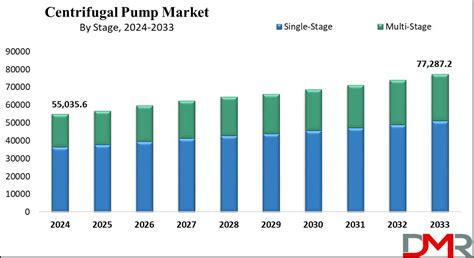

The global centrifugal pump market size was valued at USD 50.42 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 3.5% from 2023 to 2030.The economic value generated by the centrifugal pump industry was estimated at approximately USD 37.5 billion in 2022. The rising residential and commercial infrastructure, coupled with the expansion of the manufacturing industry globally, is expected to drive the demand for centrifugal pumps globally.

Centrifugal pumps have been used in industrial applications for many years. They are highly efficient, low-maintenance machines that can handle a wide range of fluids and temperatures. This makes them an excellent choice for a variety of industries such as oil and gas, chemical processing, water treatment, and mining. But [.]

Centrifugal Pumps Sector Outlook. The economic value generated by the centrifugal pump industry was estimated at approximately USD 37.5 billion in 2022. The rising residential and commercial infrastructure, coupled with the expansion of the manufacturing industry globally, is expected to drive the demand for centrifugal pumps globally. Centrifugal Pump Market Growth Factors. Extensive Application Across Wide Range of Industries to Boost Industry Size. The continuous need to boost pressure and supply water to conduct various operations has propelled centrifugal units in different verticals like food & beverage, marine, metal manufacturing, chemicals, and many others.Introduction. Centrifugal pumps are one of the most popular pumps used in various industries for moving fluids from one place to another. These pumps work on the principle of converting mechanical energy from a motor into kinetic energy, used to drive the fluid through the pump and into the discharge pipe.

2 Centrifugal Pump Selection Guide See page 4-5 table for list of eight color-coded market designations. . Goulds Pumps ITT Goulds Pumps is among the most widely recognized and respected brands in the global pump industry, serving customers in the oil and gas, mining, power generation, chemical, pulp and paper, and general industrial markets .

Centrifugal Fans for Petroleum, Chemical, and Gas Industry Services. 1. Scope. 1.1 . This standard covers the minimum requirements for centrifugal fans for use in petroleum, chemical, and gas industry services. Fan static pressure rise is limited to differential usually not exceeding 130 in. (330 cm) of water

Forward-curved centrifugal fans have impeller blades that can catch and hold debris, making these suitable for filtered or cleaner air applications only. Fans can be equipped with air filters to further improve air quality. These filters are designed to remove small particles and contaminants from the air stream, providing additional protection .The industry-leading centrifugal clutches from BLM Automatic Clutch are critical in countless agricultural applications. Our centrifugal clutches feature minimal downtime and maximum productivity, all while requiring minimal maintenance. BLM clutches can be applied to pumps, sprayers, chippers, and a variety of other agricultural equipment. .

Centrifugal pumps are essential in various industries, including chemical, petrochemical, food and beverage, water and wastewater treatment, power generation, mining, and construction. They are used to transfer fluids such as water, chemicals, fuels, and oils from one place to another.Sam Turbo Industry Pvt. Ltd. is an ISO 9001:2015 and ISO 45001:2018 certified company, Impeccable quality and 50 years of experience in the centrifugal pumps industry are the two major factors that gave birth to our company. Centrifugal force is the apparent force that acts away from the center of a circular path. The force is always perpendicular to the direction of movement. The formula for centrifugal force is the same as for centripetal force: F c = mv 2 /r. However, centrifugal force acts in an equal and opposite direction.Centrifugal pump is the most common pump used to transfer liquid in chemical industries. Centrifugal pump work on the principle of Bernoulli’s Law. The liquid that leaves the outer diameter of impeller enters into the internal casing wall of volume. Here it stops to collect in ever-expanding exit chamber of volume.

global centrifugal pump market size

Rousselet Robatel manufactures continuous and batch centrifugal hydro-extractors designed for applications such as wool, cotton, nylon, virgin or recycled fabrics, for hydro-extraction of bobbins, loose stock, recycled fibers, carpet recycling, hanks, fabric sheets, and clothing. Typical Applications Rousselet‐Robatel centrifugal hydro . Continue reading →

centrifugal pump types

Centrifuge, any device that applies a sustained centrifugal force—that is, a force due to rotation. Effectively, the centrifuge substitutes a similar, stronger, force for that of gravity. Every centrifuge contains a spinning vessel; there are many configurations, depending on use. . Technology Industry. centrifuge. instrument. Actions Cite .Applications of Centrifugal Separators in Engineering: Found in diverse industries like dairy, oil and gas, food and beverage, and chemical industries for effective separation tasks. Centrifugal Separation Process Explained: Involves high-speed rotation of a mixture causing denser particles to move outward, according to the formula: \( F_c = m . Centrifugal pumps are the most common dynamic pumps used in industries. They work by rotating impellers powered by electric motors to move liquids through centrifugal force. While not suitable for thick liquids, they can handle fluids with solids. These pumps are popular globally due to their durability, efficiency, low cost, and simple design . Shipbuilding Industry. Centrifugal pumps are used for bilge pumping, fire fighting, water supply, and fuel transfer tasks. Centrifugal pumps can also be used to transfer sewage and other waste materials from one location to another. In addition, these pumps are often used to create a vacuum environment within a ship’s hull during construction .

Centrifugal Pump Market Size & Trends. The global centrifugal pump market size was valued at USD 50.42 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 3.5% from 2023 to 2030. The rising residential and commercial infrastructure coupled with the expansion of the manufacturing industry globally is expected to drive the demand for .

Centrifugal fans, also called Centrifugal blowers, play an essential role in various industrial applications.You will find them widely used in HVAC systems, manufacturing processes, dust collection, and more. This comprehensive guide explores the mechanics, types, applications, and benefits of centrifugal fans, providing a detailed overview that highlights their importance .Having supplied centrifugal fans and blowers for over five decades, ACI has the proven expertise and knowledge to engineer products appropriate for demanding applications. . 50 years’ experience in supplying centrifugal fans and blowers and one of the most extensive product ranges in our industry, ACI is able to engineer individual and .

Pharmaceutical centrifuges, crucial in drug manufacturing, use centrifugal force for separation tasks. Various types, like tubular bowl, decanter, disk-stack, and ultracentrifuges, cater to different needs. . The industry is bound by rigorous regulations that mandate the safe production of pharmaceuticals while concurrently mandating a .

In this article explained about centrifugal section and Sugar house equipment capacity calculation for process house of sugar industry viz., Pug mills, Batch and continuous centrifugal machines, Magma mixers, sugar melter, pumps for magma & molasses, Superheated wash water system, Sugar hoppers, Sugar dryer, sugar elevator & grader. While these devices use several different mechanisms to transfer fluids from one point to another, a centrifugal pump is one of the most popular and commonly used pumps in industries to typically transport low viscosity fluids. This guide provides an overview of the centrifugal pump, its working principle, and some of the popular applications . Centrifugal pumps are the most common types of pumps used in the oil and gas industry. Centrifugal pumps use centrifugal force through the rotation of the pump impeller to draw fluid into the intake of the pump and force it through the discharge section via centrifugal force. The flow through the pump is controlled by discharge flow control valves.

Increased pressure: Centrifugal fans can overcome higher system resistance. Energy efficiency: Centrifugal fans are relatively efficient, as the energy required to move the air increases with the cube of the air velocity, whereas the power required to drive a centrifugal fan increases only with the square of the air velocity. Partnering with a Centrifugal Pump Supplier. Selecting the right centrifugal pump type is obviously #1, but choosing a process pump supplier who understands your specific needs is just as important. At DXP, we provide top-notch centrifugal pump solutions for various industries. Let’s optimize your pumping process together!

lab depot pipette bulbs

A centrifugal pump is used to move water and other low viscosity liquids with the assistance of centrifugal force. The pump uses a motor that converts electric energy into mechanical energy. This energy initiates the rotation of the pump’s impeller and helps move the liquid from a lower to a higher level.

lab disposable plastic pipette tips

centrifugal pump market share

Autoclave Engineers Bolted Closure pressure vessels for high-temperature and high-pressure research.

centrifugal industry|centrifugal pump designs